Reading “Architecture for the Poor”

Hassan Fathy Rediscovers Traditional Egyptian Architecture

In this my third Substack text I am going to try something a little different: a running commentary on a text that I have read many times and that I find meaningful and inspirational. The text is from the book Architecture for the Poor, published in 1969, by the Egyptian architect, Hassan Fathy1.

As a young man growing up in a well to do urban family Hassan Fathy had a dream of building not single houses, but entire villages: a not uncommon dream (or fantasy) among many people in his days and ours. His family owned land which they leased out to tenant farmers and young Fathy could never accept that the peasants lived in such poorly built homes. At least the peasant had a home of his own, unlike the more comfortable middle class, who had somehow lost the ability build their own homes.

“Surely it was an odd situation that every peasant in Egypt with so much as an acre of land to his name had a house, while landowners with a hundred acres or more could not afford one. But the peasant built his house out of mud, or mud bricks, which he dug out of the ground and dried in the sun. And here, in every hovel and tumbledown hut in Egypt, was the answer to my problem. Here, for years, for centuries, the peasant had been wisely and quietly exploiting the obvious building material, while we, with our modern school-learned ideas, never dreamed of using such a ludicrous substance as mud for so serious a creation as a house.

So I started to design country houses in mud brick… These houses, mostly for rich clients, were certainly an improvement on the old town type of country house, but largely because they were more beautiful. In spite of their economical mud brick walls, they were not so very much cheaper than houses built of more conventional materials, because the timber for the roofs was expensive.

Soon afterwards the war started, and all building stopped. Steel and timber supplies were completely cut off, and the army requisitioned such materials as were already in the country. Yet, still obsessed by my desire to build in the country, I looked about for ways of getting round the shortage. At least I still had mud bricks! And then it occurred to me that, if I had mud bricks and nothing else, I was no worse off than my forefathers. Egypt had not always imported steel from Belgium and timber from Rumania, yet Egypt had always built houses. But how had they built? Walls, yes. I could build walls, too, but I had nothing to roof them with. Couldn't mud bricks be used to cover my houses on top? What about some sort of vault?”

As far as Fathy knew, building a vault required a wooden centering, using both materials and skills beyond the means of most peasants. Tasked with rehabilitating some of the structures on a farm belonging to the Royal Society of Agriculture, he even attempted to build vaults without centering, together with skilled local masons, but failed miserably at each attempt. Hearing about his troubles, an elder brother (an engineer working at the Aswan Low Dam) mentioned seeing freestanding vaults built by Nubian peasants. Perhaps Fathy would like to come up to learn more?

“One morning in February 1941 I got off the train at Aswan, in company with a number of students and teachers from the School of Fine Arts… On entering the first village, Gharb Aswan, I knew that I had found what I had come for. It was a new world for me, a whole village of spacious, lovely, clean, and harmonious houses each more beautiful than the next. There was nothing else like it in Egypt; a village from some dream country… whose architecture had been preserved for centuries uncontaminated by foreign influences. Not a trace of the miserly huddle of the usual Egyptian village, but house after house, tall, easy, roofed cleanly with a brick vault, each house decorated individually and exquisitely around the doorway with moldings and tracery in mud.”

Nothing less than a miracle! Here had survived, in unbroken tradition stretching back many millennia, an autochthonous2 way of building that had been lost somewhere somehow during the millennia in the more cosmopolitan, lower Egypt:

“I realized that I was looking at the living survivor of traditional Egyptian architecture, at a way of building that was a natural growth in the landscape, as much a part of it as the doum palm tree of the district. It was like a vision of architecture before the Fall: before money, industry, greed, and snobbery had severed architecture from its true roots in nature.”

And Fathy was not alone in his delight. A modern artist would probably refuse to fall for “mere” beauty, but not Fathy’s classically trained colleagues:

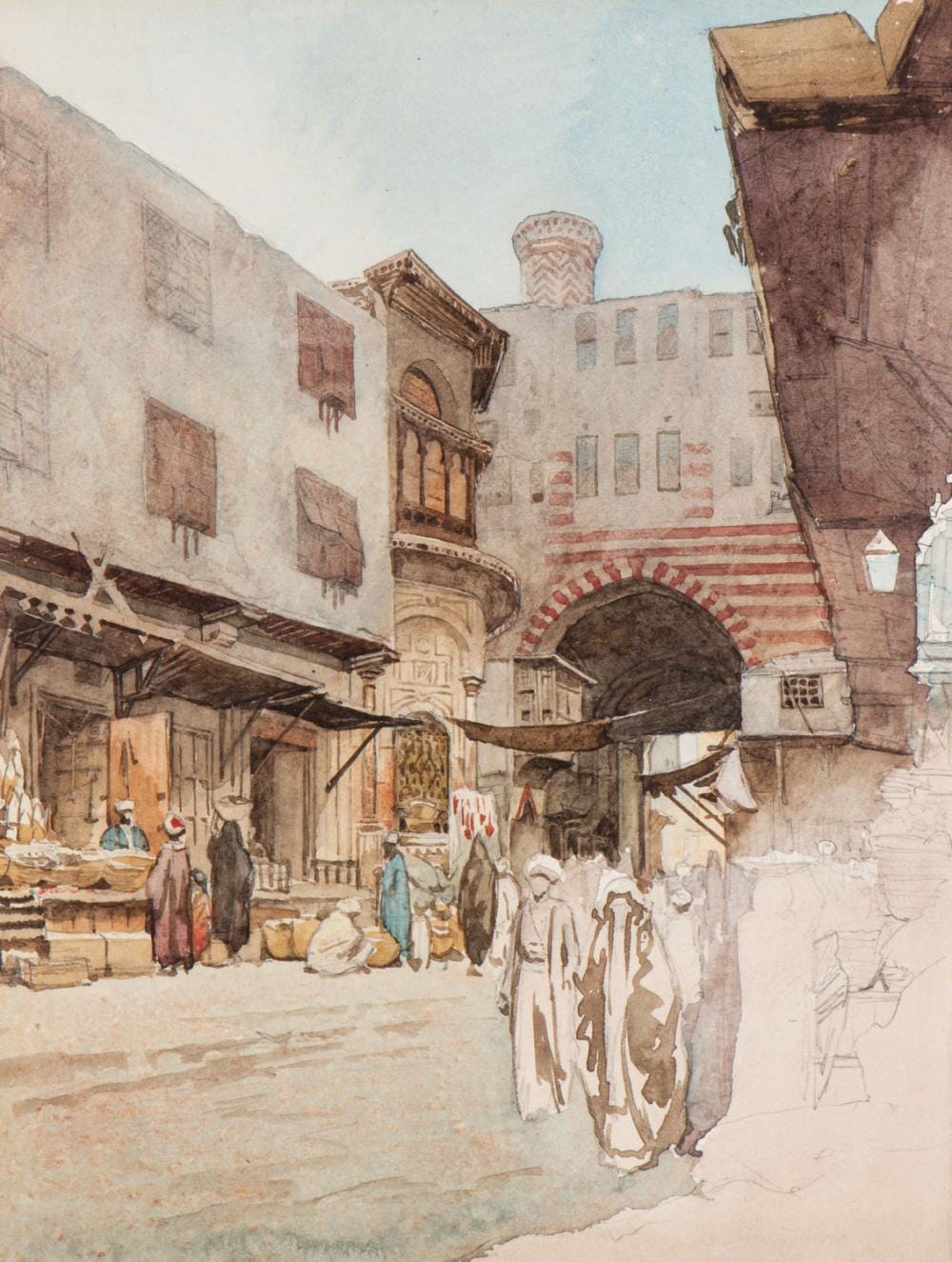

“If I was delighted, the painters who had come were in ecstasies. At every corner they sat down, unwrapped canvases, put up easels, seized palette and brush, and set to. They started, exclaimed, pointed; it was a gift in a million for an artist.”

For Fathy in 1941, just as for any serious person today, there is always the healthy skepticism to unfamiliar ideas: how well can mud bricks in free vaulting survive daily use? Is the method and material robust enough to withstand rains, floods, earthquakes and wars? Fathy had to find out for himself:

“The next day our party went to see the Fatimid Cemetery at Aswan. This is a group of elaborate shrines, dating from the tenth century, built entirely in mud brick, where vaults and domes are employed with splendid assurance and style. There is also, close to Aswan, the Monastery of St. Simeon, a Coptic building of the same period. Here too mud brick domes and vaults are employed, but the simplicity and humility of the monastic ideal is revealed in the architecture, which thus proves able to accommodate equally well the contrasting inspirations of the Moslem and Christian religion. Among other things, I noticed with great surprise and interest that the refectory held a broad gallery, supported entirely upon an ingenious system of main and secondary vaults to avoid a heavy filling between the curved surface of the vault and the horizontal floor above it. This showed argument that mud brick buildings could go up to two stories and still be strong enough to survive for a thousand years. I was getting more and more confirmation of my suspicions that the traditional materials and methods of the Egyptian peasant were more than fit for use by modern architects, and that the solution to Egypt's housing problem lay in Egypt's history.”

As is so often the case: the way forward was to look backwards!

Now Fathy had to find a skilled builder to take back to Egypt proper and teach him and his crew the secrets of Nubian vaulting. Since the typical Nubian peasant built his own home, professional builders were hard to find, there was simply no demand for them, but eventually Fathy found a few who agreed to join him in lower Egypt later on. But first Fathy had some more stops to do on this field study.

“After Aswan, we went to Luxor… to examine the granaries of the Ramesseum—long vaulted storehouses, built of mud brick 3,400 years old. It seemed to be a fairly durable substance.”

Yes quite. Modern catalogue homes and developer built homes usually come with warranties from 6 to 24 months, although sometimes a warranty can be extended up to 10 years for major structural problems.

“When I was back in Cairo, I wrote immediately to Aswan for masons. There was no time to lose, for the Royal Society of Agriculture's farm was still roofless after the collapse of our first attempt at vaulting. In a few days I had met Abdu Hamed and Abdul Rahim Abu en Nur—masons from Aswan—and the next day they were working on the farm… for £E3.40 we had a room 3m x 4m built in one and a half days. In concrete it would cost about £E16, in timber £E20.3”

Building during wartime! It is when we experience constraints and limits that we truly get inventive. By using only the materials that could be found on the site, the work was both faster and cheaper. Nothing was imported. No supply chains, no waiting for deliveries, no carbon emissions in manufacturing or transporting. Unlike today, during building, no special site electricity was needed The only ingredients were soil, water, and straw, and that they had in abundance.

While the Nubian masons started working, Fathy and his team of Egyptian laborers helped out with making mud bricks, simple work that anyone could perform with simple tools and safe materials after a mere few minutes of instruction. The Nubian bricks were a little different than the Egyptian bricks they were used to making: they had to be lighter (so a higher percentage of chopped straw was added to the mix) and they had to be marked with two parallel groves (made in a couple of seconds with the touch of a finger), to create the suction effect that would enable them to stick together. And here we get a little technical, you can skip this next bit if you wish, it is just a description of two Nubian masons with a single simple hand tool, building in a day and half, a vault that can stand for 5000 years (I have a thread about this on Twitter4):

“At the scene of our failure the walls were still standing although our attempt at a vault had collapsed. In each room there were two side walls, three meters apart, and an end wall somewhat higher against which the vault was to be built. The masons laid a couple of planks across the side walls, close to the end wall, got up on them, took up handfuls of mud, and roughly outlined an arch by plastering the mud onto the end wall. They used no measure or instrument, but by eye alone traced a perfect parabola, with its ends upon the side walls. Then, with the adze, they trimmed the mud plaster to give it a sharper outline. Next, one at each side, they began to lay the bricks. The first brick was stood on its end on the side wall, the grooved face flat against the mud plaster of the end wall, and hammered well into this plaster. Then the mason took some mud and against the foot of this brick made a little wedge-shaped packing, so that the next course would lean slightly towards the end wall instead of standing up straight. In order to break the line of the joints between the bricks the second course started with a half-brick, on the top end of which stood a whole brick. If the joints are in a straight line, the strength of the vault is reduced and it may collapse. The mason now put in more mud packing against this second course, so that the third course would incline even more acutely from the vertical. In this way the two masons gradually built the inclined courses out, each one rising a little higher round the outline of the arch, till the two curved lines of brick met at the top… Thus the whole vault could be built straight out in the air, with no support or centering, with no instrument, with no drawn plan; there were just two masons standing on a plank and a boy underneath tossing up the bricks, which the masons caught dexterously in the air, then casually placed on the mud and tapped home with their adzes. It was so unbelievably simple. They worked rapidly and unconcernedly, with never a thought that what they were doing was quite a remarkable work of engineering, for these masons were working according to the laws of statics and the science of the resistance of materials with extraordinary intuitive understanding.”

The human hand is surely the most phenomenally versatile and exact instrument we will ever know.

“In this way it became possible to construct the roof with the same earth bricks as for the walls. Indeed, to span three meters in mud brick is as great a technical feat, and produces the same sense of achievement, as spanning thirty meters in concrete.

The simplicity and naturalness of the method quite entranced me. Engineers and architects concerned with cheap ways of building for the masses had devised all sorts of complicated methods for constructing vaults and domes. Their problem was to keep the components in place until the structure was completed, and their solutions had ranged from odd-shaped bricks like bits of three-dimensional jigsaw puzzles, through every variety of scaffolding, to the extreme expedient of blowing up a large balloon in the shape of the required dome and spraying concrete onto that. But my builders needed nothing but an adze and a pair of hands. Within a few days all the houses were roofed. Rooms, corridors, loggias were all covered with vaults and domes; the masons had solved every problem that had exercised me (even to building stairs). It only remained to go out and apply their methods throughout Egypt.”

Indeed. Let’s look to what has worked in the past, let’s make the most of the opportunities presented to us by the limitations we build under: lets build with what we have, where we are, to the best of the combined ability and know-how of all generations of our ancestors, not just the conceited one generation that happens to be trampling around right now, messing things up.

Thank you for reading this rather long text. Since childhood, us moderns have been literally brain-washed with the idea that progress is good and progress is inevitable and old things are automatically worse than new things. G.K. Chesterton famously wrote: “My attitude toward progress has passed from antagonism to boredom. I have long ceased to argue with people who prefer Thursday to Wednesday because it is Thursday.” I imagine that Hassan Fathy would have agreed. He dared to imagine a different way of building homes, and let himself be inspired by his ancestors. He had faith that they were no simpletons just because they had lived a few hundred or a few thousand years before “to-day”. By working with nature / limitations / undeniable economical and social circumstances, rather than against them, he came up with a plan for how to work around the problems at hand after having satisfied himself of the general soundness of his plans. All in all, not a bad example to study.

autochthonous (adjective): Native to the place where found; indigenous.

The currency of Egypt from 1834, is the Egyptian pound, or £E, (standing for livre égyptienne, in French). The £E is divided into 100 piastres, or pt.